Setting up an MPG Jog Pendant in LinuxCNC

CNC jog pendants are super useful devices for quick setup and configuration of CNC machines. A quick search for CNC jog pendant on AliExpress turns up a bunch of results. For this post, I'll cover connecting a wired jog pendant with ESTOP to a Mesa 5i25 FPGA card to control a 3 axis CNC mill.

The config below works for me. The plethora of hardware configs out there mean this article likely won't work for you verbatim, but it's my hope that it provides a good starting point for other configs.

Please note that I got this config working on LinuxCNC 2.9.0-pre0. It should also work on 2.8.*, but will not work on anything before the joints/axes split.

Hardware

This is the jog pendant I'll be using.

It provides estop, axis select, multiplier and encoder outputs on a bunch of bare wires as seen in

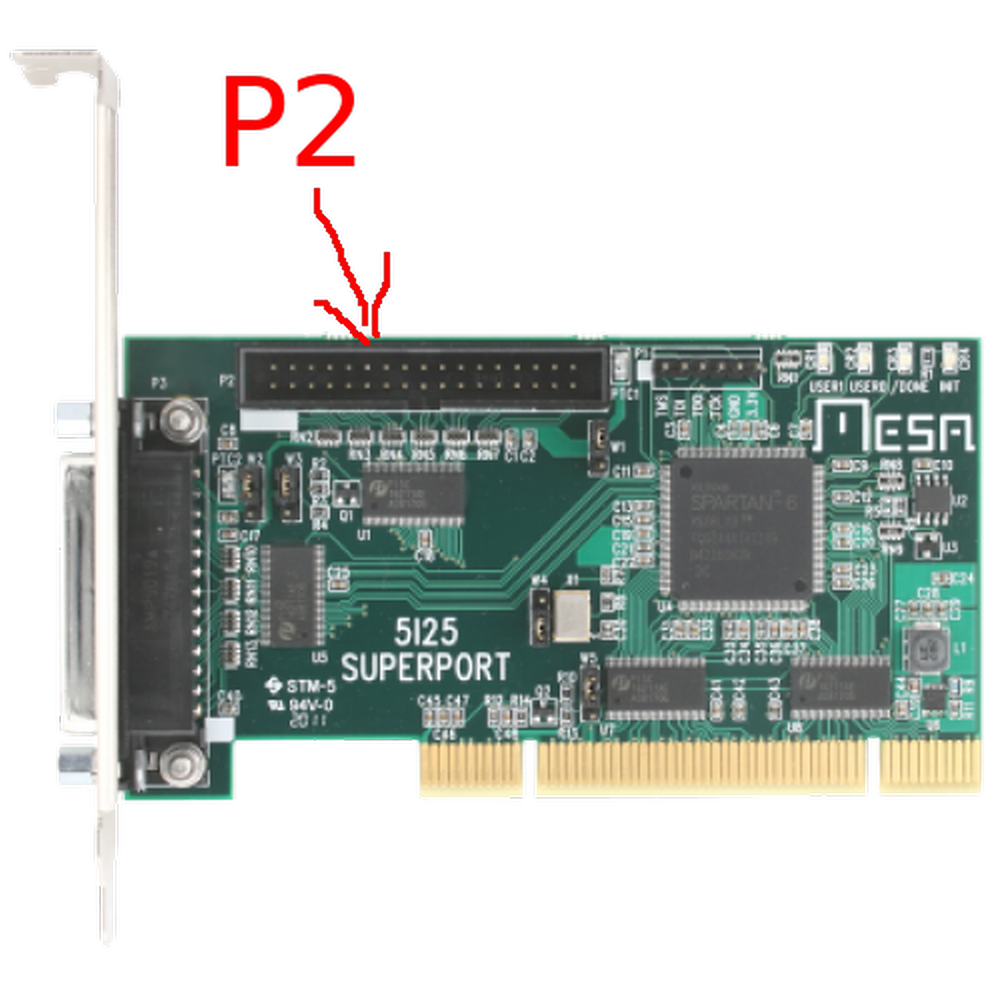

the image. I'm going to connect it to the internal P2 connector of a Mesa 5i25 FPGA card, so I'll

trim the bare wires and solder them to a DB25 cable-end connector in a bit.

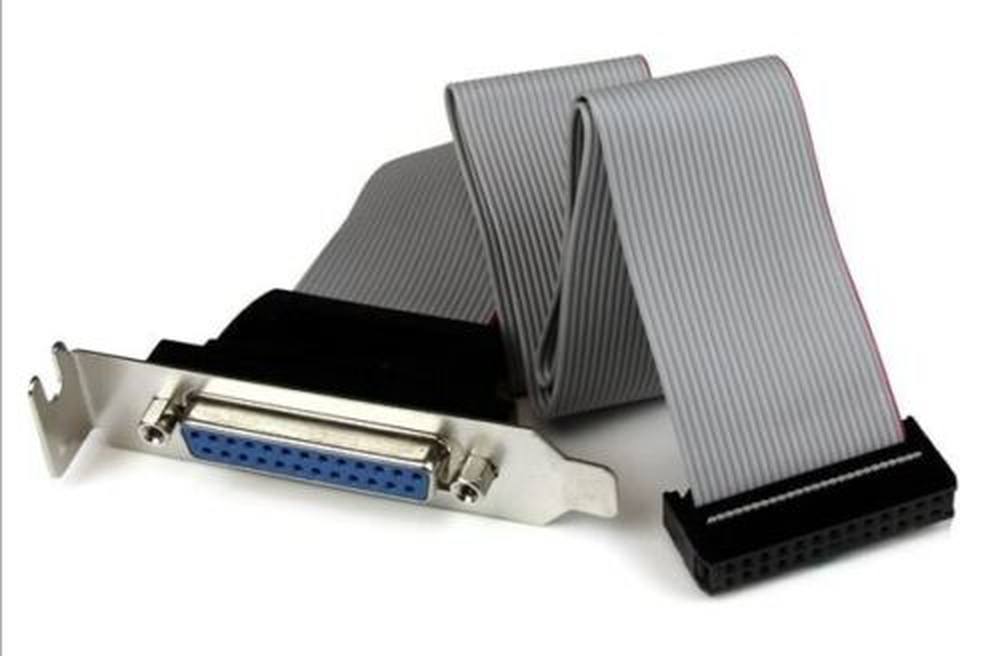

I'm using a Mesa 5i25 FPGA card through a DB25 breakout cable (like

this one) connected to P2. Other Mesa cards with

parallel port breakout options like the 6i25 should also work, but are untested.

The Mesa card can optionally provide +5V to external circuitry on the last 4 pins of the parallel

port connector. This must be enabled for the jog pendant to work. From the manual, ensure that

jumper W1 is in the UP position.

For reference, here's an image of the breakout cable:

Soldering up the jog wheel connector

We now need to solder a DB25 connnector to the jog pendant cable so it can be plugged into the Mesa card. The exact pinout doesn't matter too much as connections can be remapped in software, but in my setup the jog wheel encoder is bound to pins 11 and 12.

This is the full pinout:

| Name | DB25 connector pin | Hostmot2 GPIO (we'll use this later) | Wire colour |

|---|---|---|---|

| ESTOP | 4 | gpio.023 | Blue/black |

| ESTOP gnd | 21 | - | Blue |

| Encoder +5V | 25 | - | Red |

| Encoder gnd | 20 | - | Black |

| Encoder A | 11 | encoder.01.input-a | Green |

| Encoder B | 12 | encoder.01.input-b | White |

| Encoder A- | - | - | Purple |

| Encoder B- | - | - | Purple/black |

| Common | 19 | - | Orange/black |

| Select axis X | 1 | gpio.017 | Yellow |

| Select axis Y | 14 | gpio.018 | Yellow/black |

| Select axis Z | 2 | gpio.019 | Brown |

| Select axis 4 | 5 | - | Brown/black |

| X1 | 15 | gpio.020 | Grey |

| X10 | 3 | gpio.021 | Grey/black |

| X100 | 16 | gpio.022 | Orange |

| LED+ | - | - | Green/black |

| LED- | - | - | White/black |

Encoder +5V, Encoder gnd and Common are connected to ground and +5V, with the 5V supplied by

the last 4 pins by enabling the auxiliary power on the Mesa card by setting jumper W1 to the UP

position.

I'm leaving the inverted signals of the encoder disconnected for simplicity. If you need the noise suppression features of differential wiring, you'll need to add some external circuitry to deal with that - the Mesa encoder inputs are single-sided.

I'm also leaving the enable LED disconnected because I can't be bothered to hook it up.

Mesa card configuration

I'm using the 5i25_prob_rfx2 bitfile for the Mesa 5i25. It seems to be a pretty general purpose

config for these cards. Other configs might work, but the pinout could be different so YMMV.

The pendant is mostly simple GPIO, but you'll need to add an extra encoder to your Mesa config when

loaded. In your <machine name>.hal file, find the loadrt line and change it:

- loadrt hm2_pci config="firmware=hm2/5i25/5i25_prob_rfx2 num_encoders=1 num_pwmgens=0 num_stepgens=3"

+ loadrt hm2_pci config="firmware=hm2/5i25/5i25_prob_rfx2 num_encoders=2 num_pwmgens=0 num_stepgens=3"

This will add an extra encoder called encoder.01 for the HAL config to use later.

The above hm2 config is for a 3 axis mill with a spingle encoder. Because I'm already using one

encoder for the spindle, I'm upping the encoder count to 2. This puts the second encoder signals

on pins 11 and 12 of the DB25 connector on P2 which we'll use for the jog pendant. If you've got a

different number of encoders, you might have to change the connector pinout in the table above or

use a completely different Mesa card/tutorial. Sorry.

Jog pendant HAL configuration

Create a new HAL file called mpg.hal and add the following:

# MPG (jog wheel) config

#

# MPG is plugged into secondary (internal) connector via a DB25 breakout cable. Pinout can be found

# at https://wapl.es/cnc/2020/02/23/linuxcnc-jog-wheel-setup.html

#

# This config requires `numencoders=2` when loading the Mesa component. It uses the second encoder,

# as the first is connected to the spindle motor

# Add component to mux axis selection into the selected axis

# --- JOINT-SELECT-A ---

# --- JOINT-SELECT-B ---

# --- JOINT-SELECT-C ---

# --- JOG-INCR-A ---

# --- JOG-INCR-B ---

# --- JOG-INCR-C ---

# --- ESTOP-EXT ---

# ---jogwheel signals to mesa encoder - shared MPG---

# ---mpg signals---

# for axis x MPG

# for axis y MPG

# for axis z MPG

# connect selectable mpg jog increments

# Note that increments of 0.025 scale to 0.1 due to 4x scaling of encoder pulses vs clicks

Some observations:

- I'm using the

in_notinverted pin values. The 5i25 has weak pullups, so pins are active low and default to high (TRUE). - I'm using

mux16instead ofmux4because I'm lazy. - Because the jog wheel is a quadrature encoder, there are 4 counts per "click". The jog scales of

0.00025,0.0025, etc are the1x,10xand100xmarkings on the pendant panel divided by 4. - The

selected-jog-incr,joint-select-*andjoint-selected-countsignals are wired to both thejointandaxissignals. This is required to make the axes move after homing, and is a result of the joints/axes split that happened around LinuxCNC 2.8/2.9.

Finally, to load this extra HAL config into the machine, add a line to the [HAL] section in

<config name>.ini:

[HAL]

HALUI = halui

HALFILE = <config name>.hal

+ HALFILE = mpg.hal

POSTGUI_HALFILE = postgui_call_list.hal

SHUTDOWN = shutdown.hal

Now you should be good. If something's not working check the HAL Meter for GPIO states and

encoder.01 values.